R&D POLICY

ERA has established and maintains procedures ensuring that our design activities are controlled, verified and meet specified requirements. The development process used is key in meeting customer expectations and maintaining a leadership position in design innovation and product quality. Project teams are responsible for ensuring that design output requirements are documented and verified against input requirements. The main documents are;

- Over 50 years of experience in electronics design and products development

- Customer Requirements & Specifications

- Customer Requirements Case by Case Analyses

- Design FMEA

- Concept Design

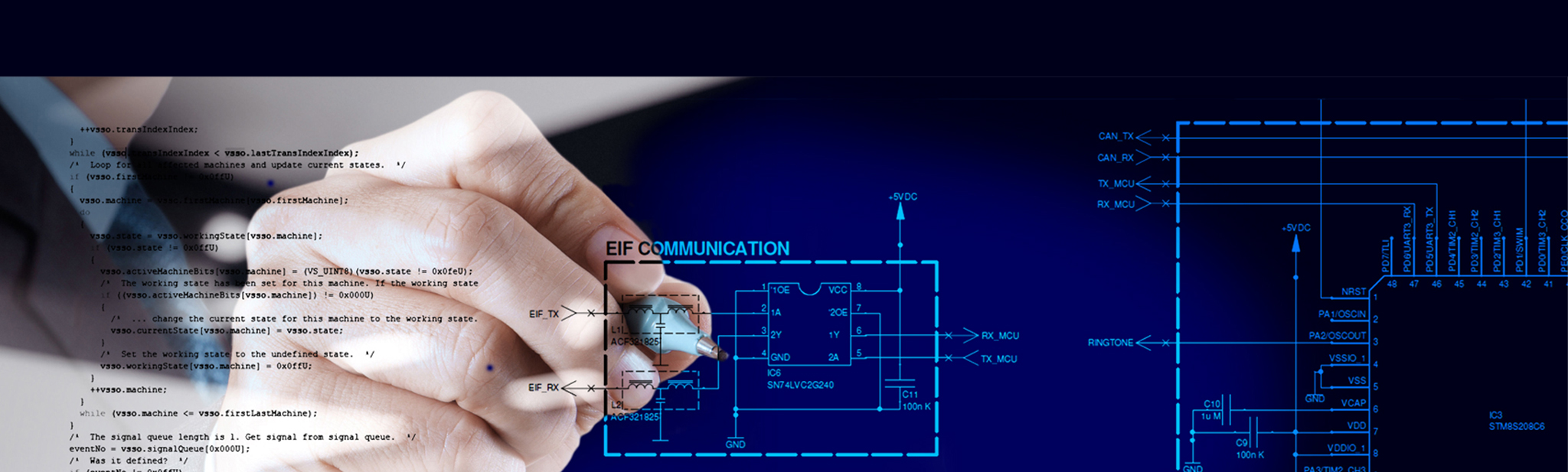

- Electronic Schematic Diagrams

- PCB Design Drawings

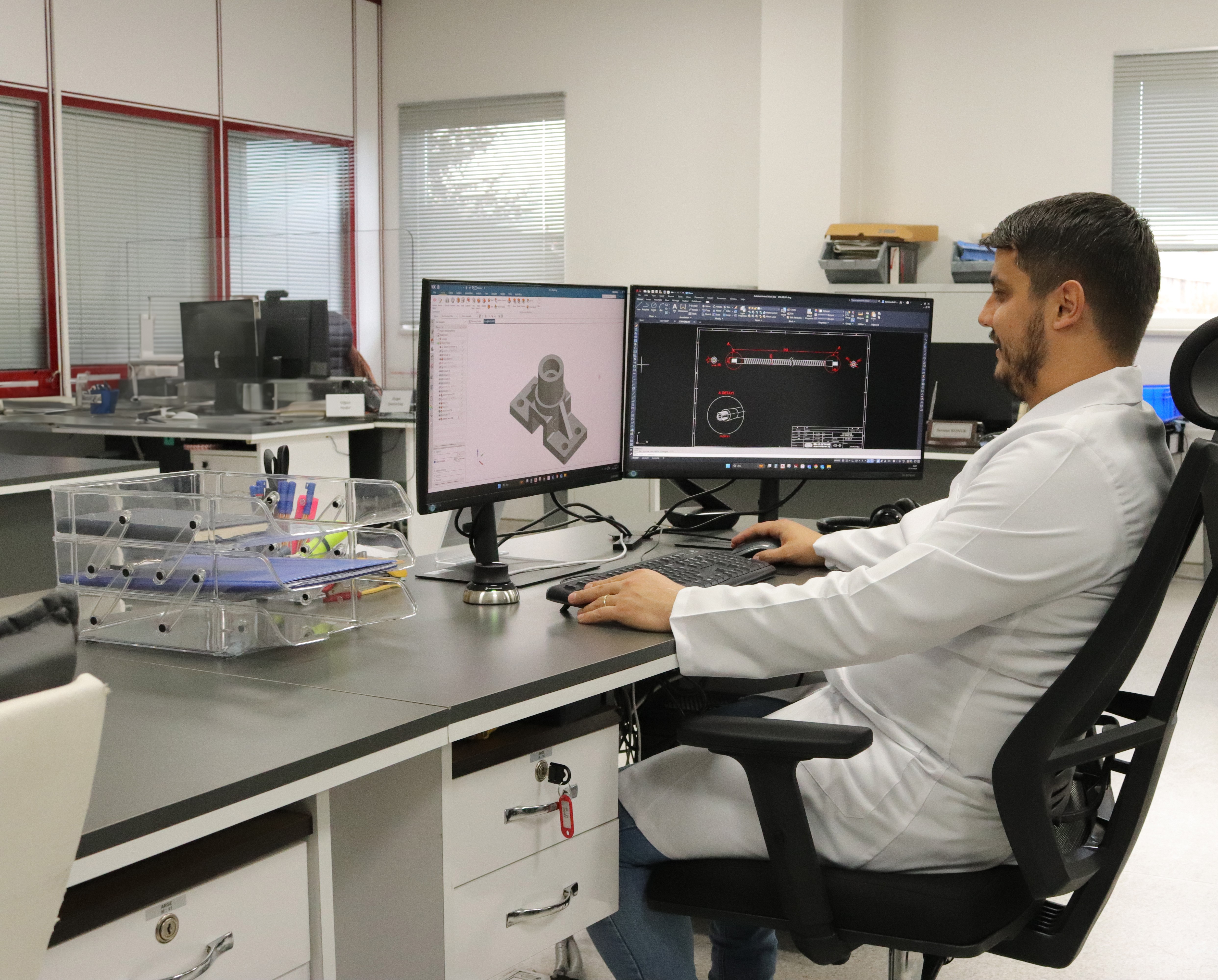

- Mechanical Design Drawings

- Optical Design

- Parts Lists

- Test Procedures

- FAI Documents

R&D PROJECT MANAGEMENT

Project management is the process of leading the work of a team to achieve all project goals within the given constraints. This information is usually described in project documentation, created at the beginning of the development process.

Key components of project management are:

- Time – the intended duration of the work

- Cost – the budget allocated for the work

- Scope – what innovations or changes will be delivered by the project

- Quality – the standard of the outcome of the project.

We manage the projects as per ISO 21500 standard (Guidance of Project Management).

Each R&D project has a R&D Project Leader who is responsible on technical requirements, project budget and project time plan and reports to R&D Manager and Integrated Project Team Lead (IPT Lead) and they report to Technical Director and Managing Director.

IPT Lead manages the Project processes, budget and timeline with R&D team, sales, purchasing, suppliers, production and compliance test companies.

When we receive the Technical Specifications or Requirements of customers, we prepare our Case-by-Case form which includes all the requirements of the customer, and our commands, reply and solutions for each paragraph as the following cases:

- Complied

- Not Applicable

- Needs Modification

- Alternative Solution

We add our opinion and solutions for the items out of Complied items. So, we agree on the project requirements with our customers in the beginning.

We have a project planning as below project steps:

- MS0: Evaluation of Project Requirements:

- Sample A: Pre-Sample Model Creation:

- MS1: Conceptional Design Customer Approval:

- Sample B: Creating Prototype Sample:

- MS2: Design Approval & Design Verification:

- Sample C: Original Parts Prototype:

- MS3: Certification Tests Completion:

- Sample D: Pre-Series Trials and Samples:

- MS4: Internal Approval:

- MS5: FAI Tests & Customer Approval

- MS6: Serial Production

Our Quality Assurance team also represented with at least 1 QA Engineer in the project team.

Our project team gets approval of the R&D Manager, IPT Lead and Technical Director on each of the above steps.

When we start a project, first project team prepare DFMEA form based on our Lessons Learned data base and similar type of R&D Projects DFMEA forms.

Production team also deals the project team after Sample B level. Production team prepares the Proses Design with PFMEA, if the product processes are different than already existing products.

We have also an academic consultant and for some projects. We are working with universities on some of these R&D projects.

R&D CAPABILITY

- Easy PC PCB Designing

- AutoCAD 2D Designing

- Unigraphics 3D Designing

- Plastic Parts 3D Printer

- Metal Parts Prototypes

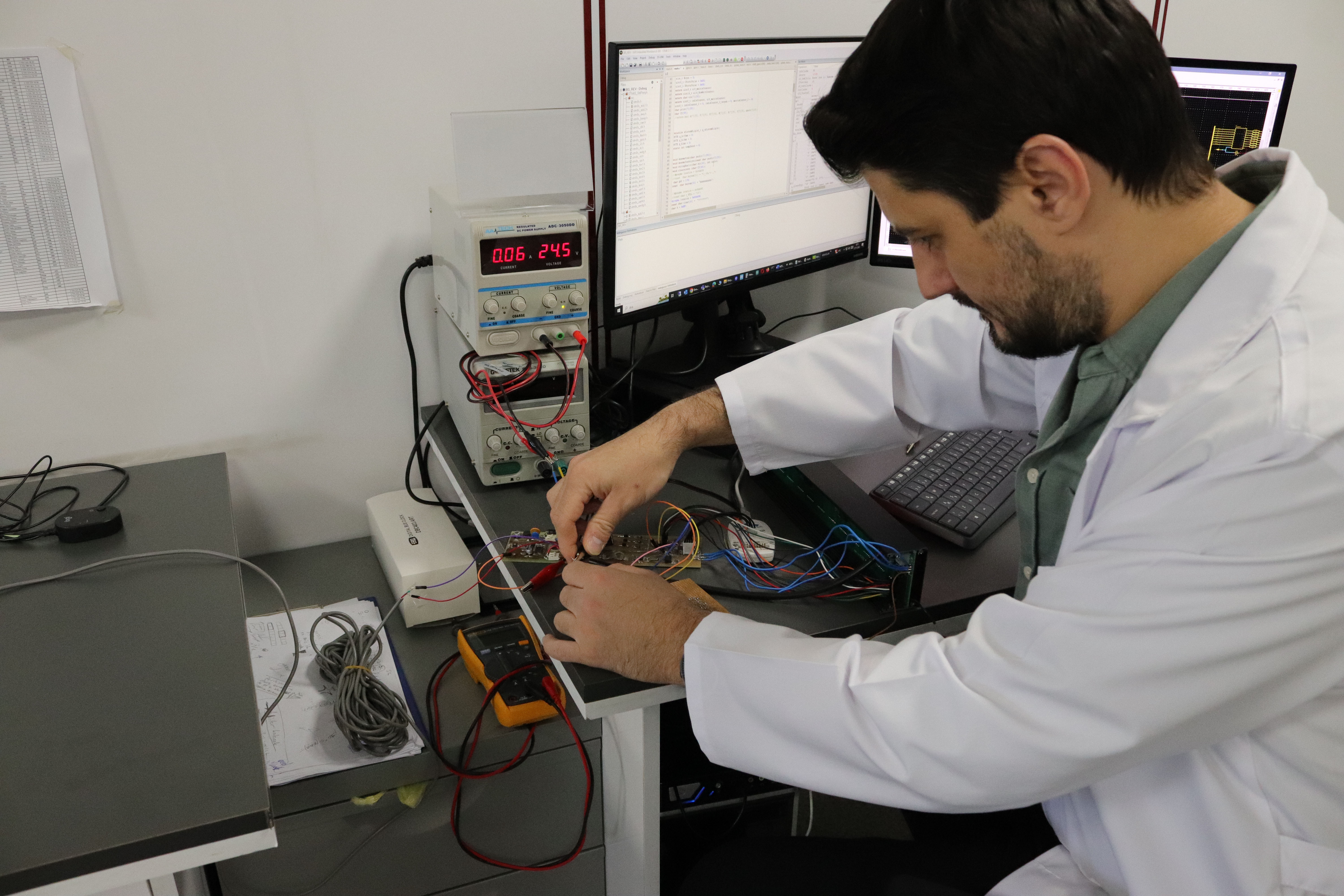

- Electronic Laboratory Tests Equipment

- Optical Design Software

- Optical Chromaticity Measuring Equipment

- Optical Simulations

- Light Level and Chromaticity Measuring

- Micro-Controller Embedded Software development

- Fast PCB Prototype Machine

- Coils & Transformers Designing & Production

- Collaboration with Universities and TTO Technology Transfer Offices

- Five TUBITAK (The Scientific & Technological Research Council of Turkey) Supported Project Completed

- Currently two TUBITAK Supported Project are Running

R&D PHASE TESTS

- Functional & Specification Tests

- ERA Special Standard Tests

- EMC Pre-compliance Tests

- Climatic Pre-compliance Tests

- Vibration Pre-compliance Tests

- Life Tests

- Arrhenius Tests

R&D STAFF

- 8 Electronics Engineers

- 2 IT Engineer

- 1 Mechatronics Engineer

- 1 Electronics Technician

- 1 IT Technician