INDUSTRIAL STRATEGY

Since the beginning ERA committed continuous development of customer-oriented targets and technology-quality focused objectives:

- Total Customer Satisfaction

- Effective Quality Assurance Systems

- Continuous Product Quality Improvement

- Innovative Efficient R&D

- Continuous Improvement of Product Quality

- JIT Compatibility

- Optimize Performance/Cost Ratio

- International Collaboration

- Investment for High Technology

- Production Efficiency Improvement

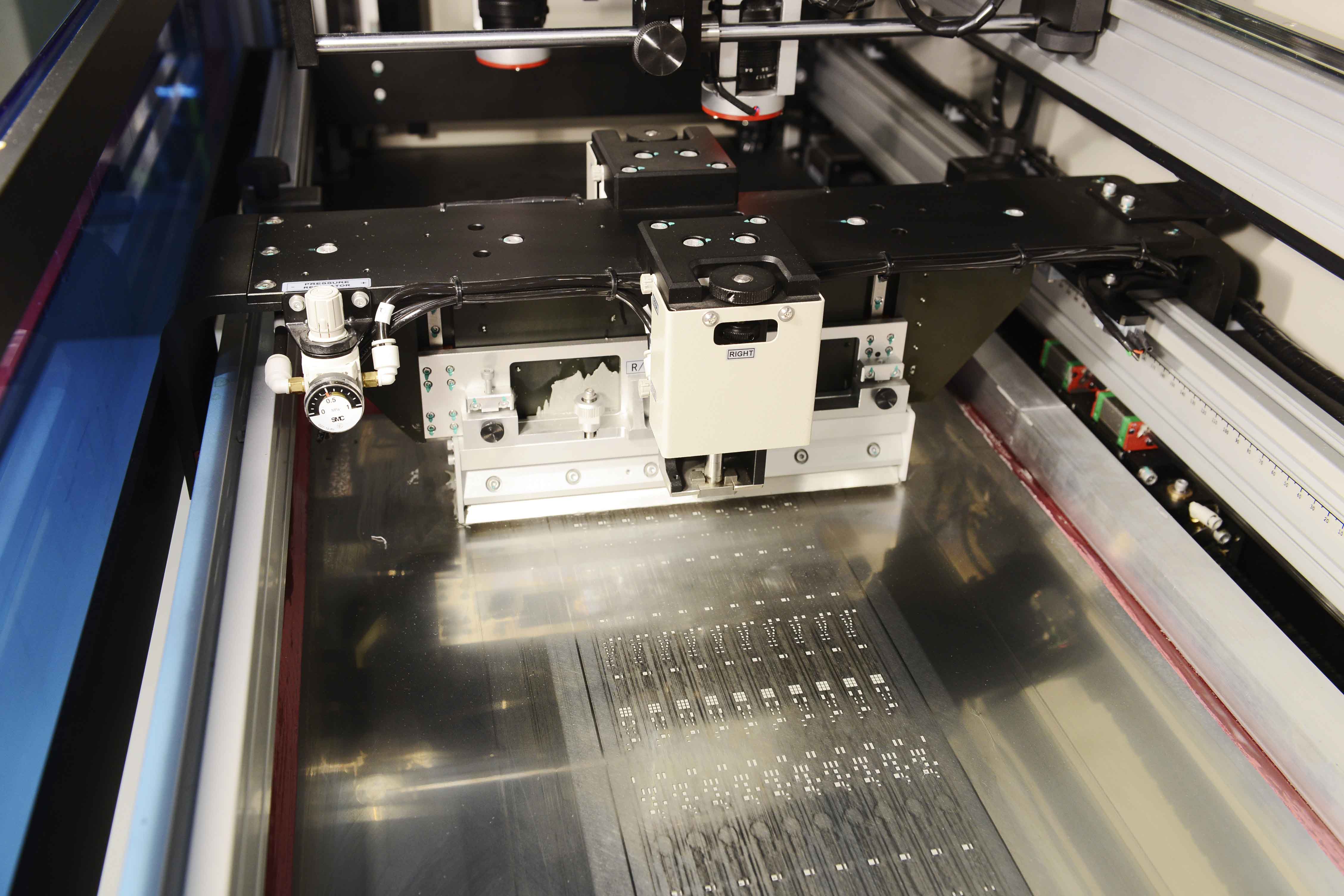

MAIN PRODUCTION MACHINES

- Component Lead Forming & Cutting: CONTACT

- Conveyor belt PCB production Lines: ATU

- Double Wave Soldering Machine: SEHO

- In-Circuit Tester: DIGITAL-TEST

- Cable Stripping & Crimping Machine: MEGOMAT

- Coil Winding Machines: STRONG SUN

- Screen Printing: ATU

- Testing Benches: VARIOUS

- LOGO Tiger

- Drawing & 3D Modelling System: Unigraphics

PRODUCTION PROCESSES

- Component Lead Forming Process

- Cable & Crimping Process

- Coil & Transformer Manufacturing

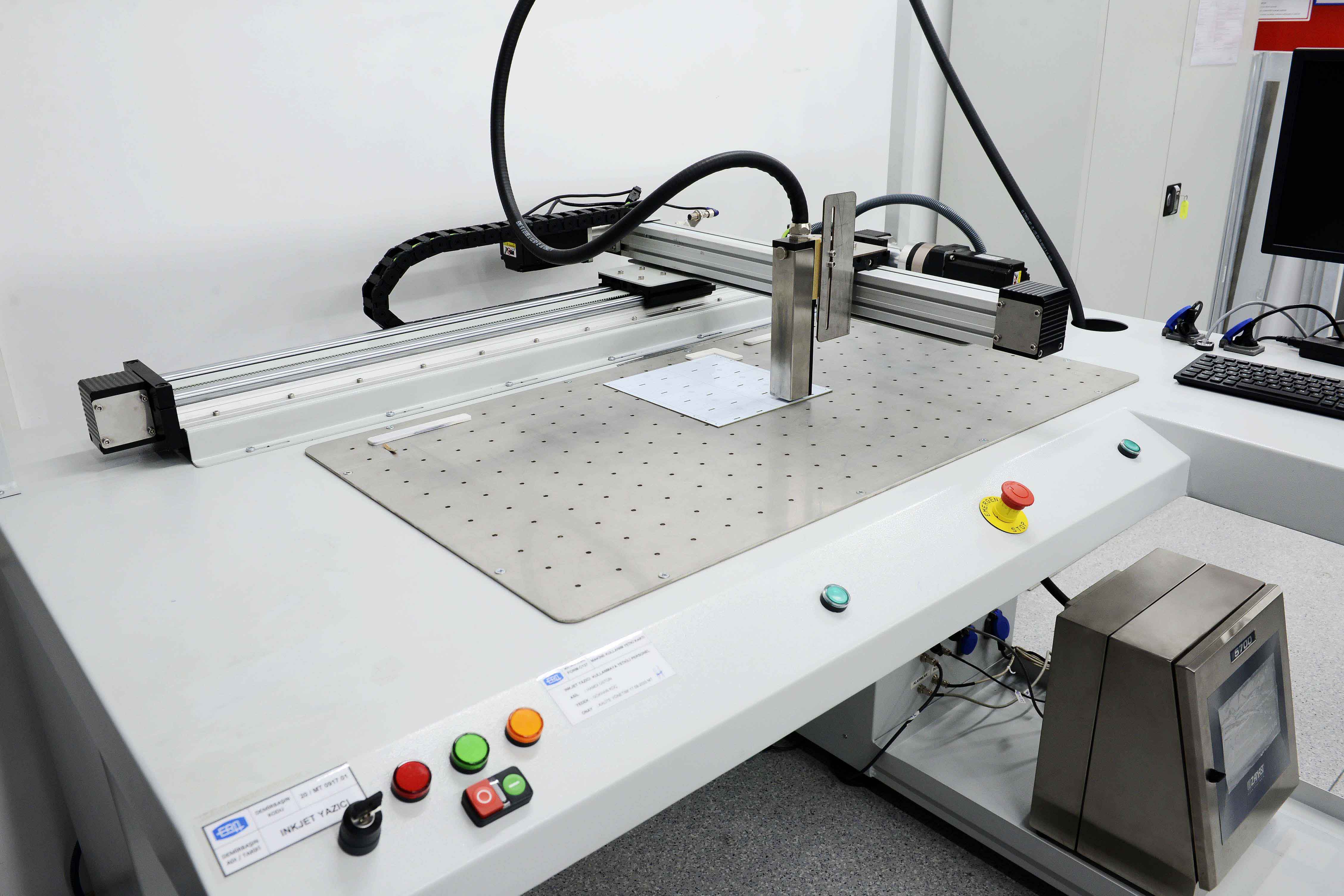

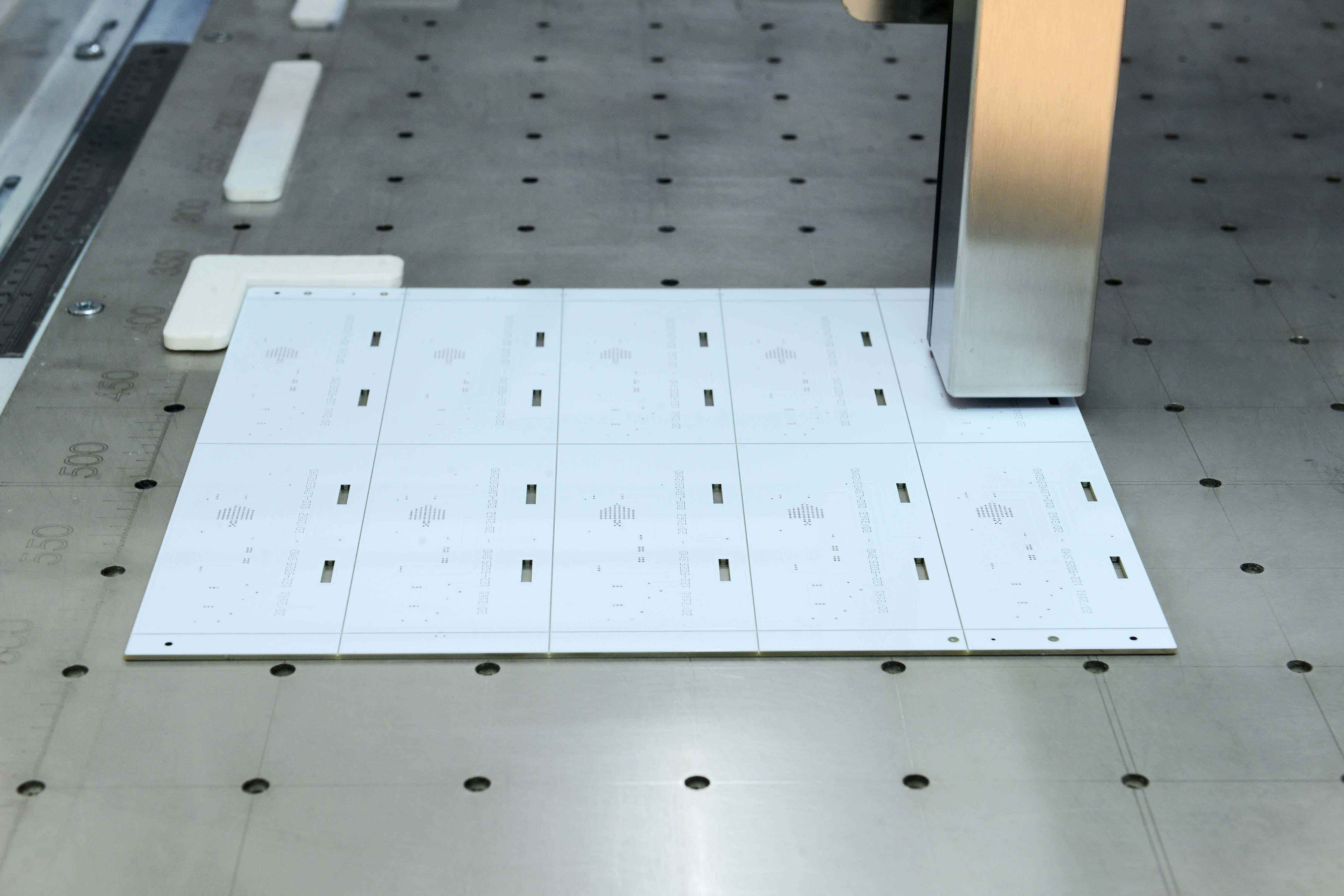

- Silk Screening

- Temperature and Humanity Controlled ESD Protected SMD Room

- Automatic Component Insertion Process

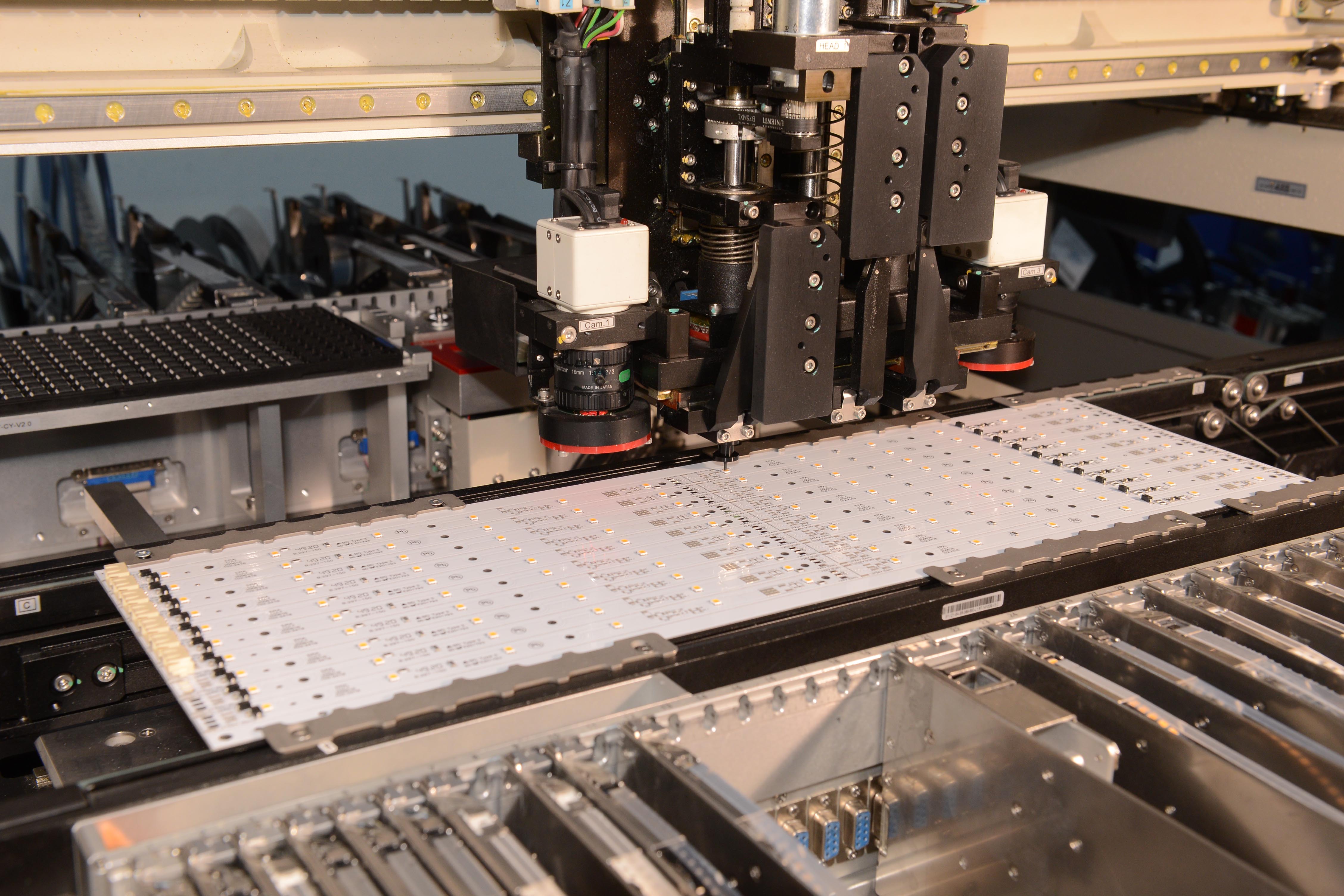

- Automatic SMD Pick & Place and Soldering

- PCB Manual Assembly & Soldering Process

- PCB Cleaning Process

- Mechanical Assembly Process

- Final Assembly Process

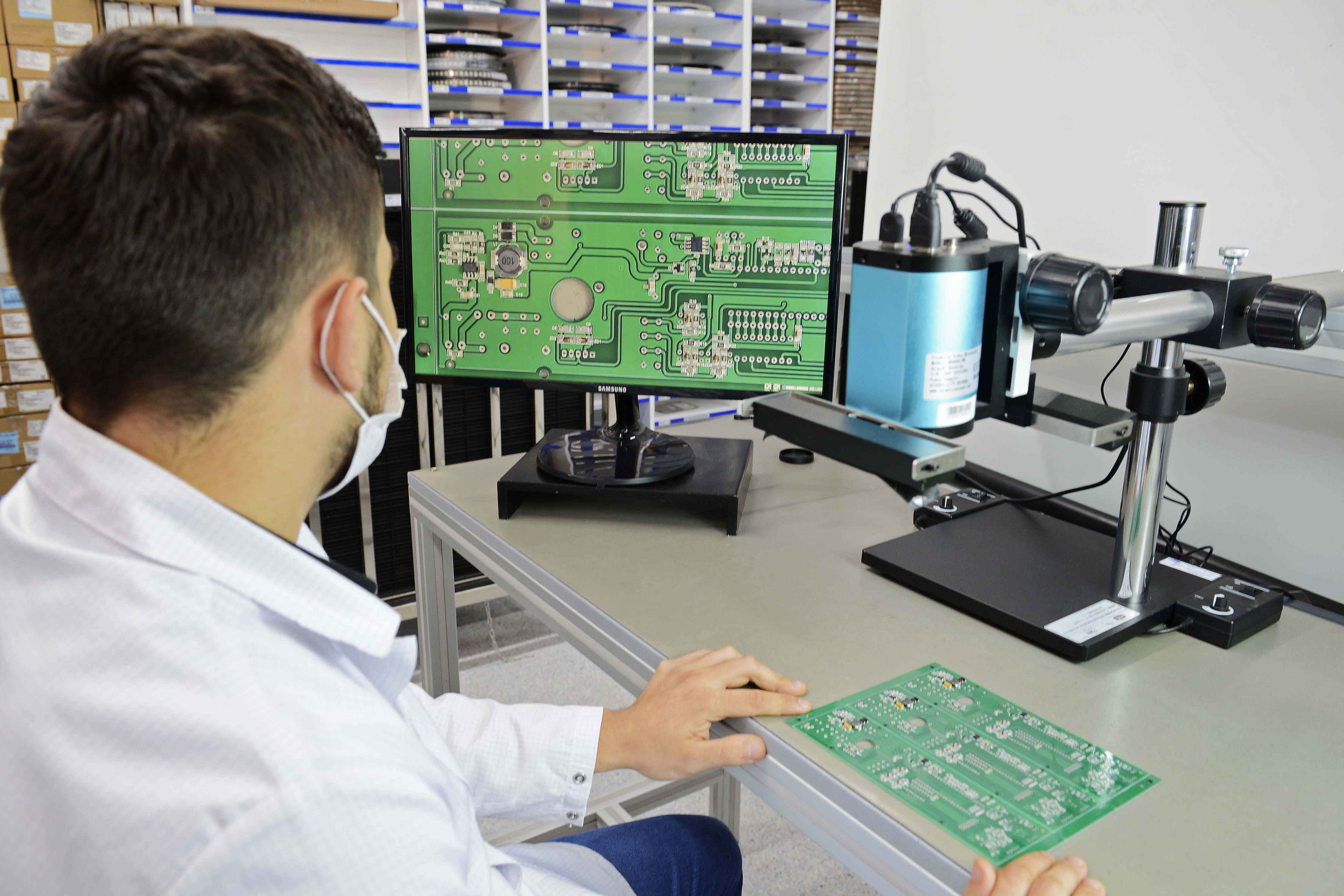

- Testing Process

- Packing Process